What is the difference between seamless, semi-seamless and welded ERW elbow?

Sayou tells you the differences on raw material, manufacturing processes, performances, appearances, sizes, applications, cost prices etc.

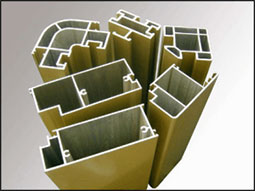

1. material and appearance differences

Seamless elbow is manufactured by the seamless steel pipe, through hot push, press or extrusion processes, no seam on the elbow body.

Welded ERW elbow is manufactured by welded steel pipe, there is a seam on the elbow body.

Semi-seamless is a mixture of seamless elbow & welded ERW elbow, small size 1/2” -2” elbow is made from seamless pipe, and size 2-1/2”-24” elbow is made from ERW pipe, but move the welding seam before they leave the material factory. Why factory make 1/2” -2” with seamless material? Because it is very difficult to move the welding seam line for above small size and its cost is very expensive.

The biggest difference between seamless elbows and welded ERW elbows are whether there is a weld line on the surface. But it is difficult to distinguish seamless elbow and semi-seamless elbow after painting. The fact is there are a lot of exporters sell this kind of fake seamless elbow to customers instead of seamless elbow.

2. Performance and Usage

Seamless steel pipe elbow has better pressure capacity and strength is higher than welded steel pipe elbow. So it is widely applied in high pressure equipment, and thermal, boiler industries. Generally the welding seam of the welded steel pipe elbow is the weak point, the quality affect overall performance.

In general, welded ERW steel pipe elbows can withhold 20% less working pressure than seamless ones. This reliability is the prime factor why people go for seamless steel pipe elbow. As a matter of fact, all the industrial pipelines are done with seamless pipe elbows only because the elbows undergo extreme thermal, chemical and mechanical workloads. Welded elbows are more preferred in aerospace, automobile and electronics industries where the budget is comparatively low, and so is the work pressure put on the pipeline. The pressure of semi-seamless elbow is more less than welded ERW elbow because the welded line is moved.

3. Available Sizes differences

For most of seamless steel pipe elbow manufacturers in China, they produce original seamless pipe elbow sizes maximum OD in 24 inch, 609.6 mm. On the contrary, welded steel pipe elbow don’t have these limitations, sizes available from 1-1/2 inch 48.3mm to 100 inch 2540 mm.

4. Cost and prices

Usually the seamless steel pipe elbow cost is higher than welded steel pipe elbow, because the raw material, manufacturing equipment and processes. . Anyway you can make orders according to your detail usage.

{{ title }}

{{ description }}